Plastics

Improved performance with lamellar talc in polyolefin compounds

Polyolefins are a versatile family of polymers known for their durability and wide range of applications, including common plastics like polyethylene and polypropylene, which we encounter daily. These plastics can be processed using methods such as film extrusion and molding to meet various production and product performance requirements.

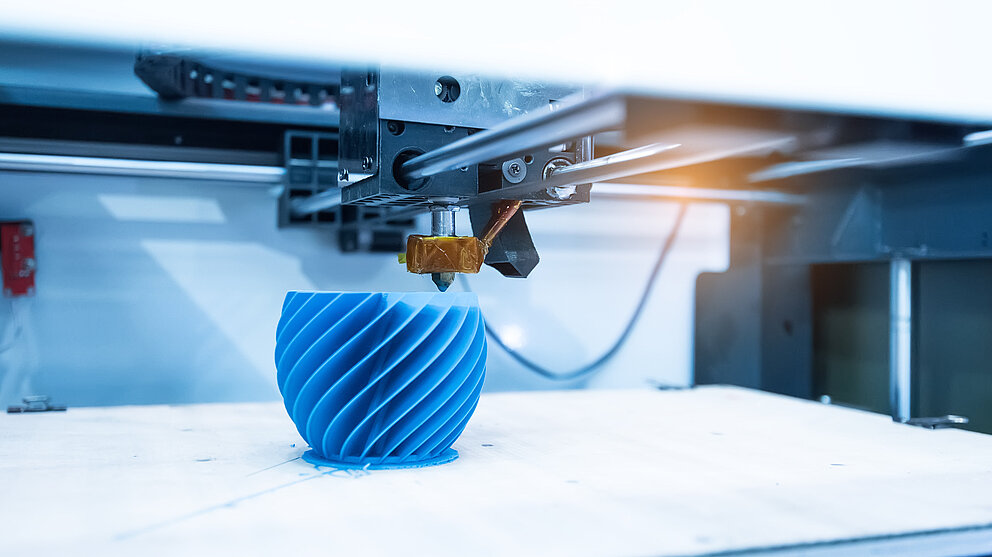

To safeguard their physical properties during high-temperature processes like injection molding or extrusion, processing stabilisers can be added. Polyethylene and polypropylene are heated to a molten state and then shaped under pressure, making them suitable for applications like thin films, fibres, and sheets. In molding, the polymer is heated and conformally shaped in a mold using techniques such as injection, blowing, extrusion, compression, and centrifugal rotation. Conversely, with 3D additive printing, molds become unnecessary.

We offer a range of functional fillers, fire-retardant enhancers, and process aids that are designed to improve the performance of compounded plastics, resulting in higher-quality products and cost savings.

Electrical & electronic equipment

A close collaborations with plastic compounders and metal processing industries

Flame retardancy plastics

Meeting halogen free environmental, health and safety requirements.

3D & additive manufacturing

Thermal stability with hectorite based multifunctional process aids

Adding future

Every day, we rely on products that enhance our comfort. Their colors, textures, and quality inspire us. That's why we incorporate meaningful, functional, and protective elements. Adding future to everyday life.